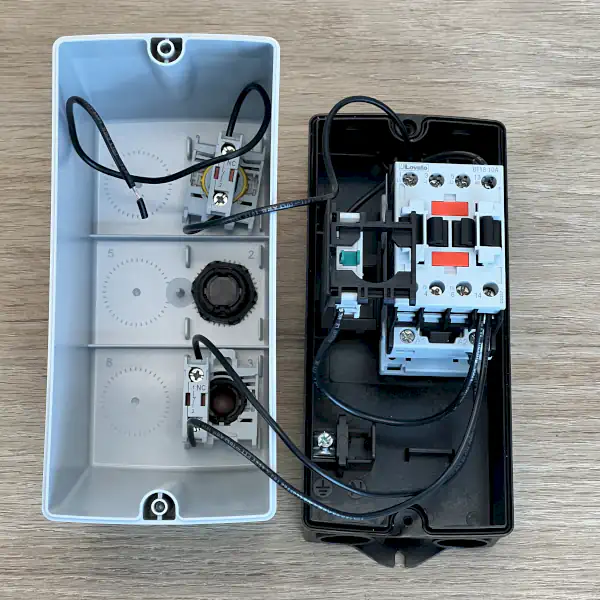

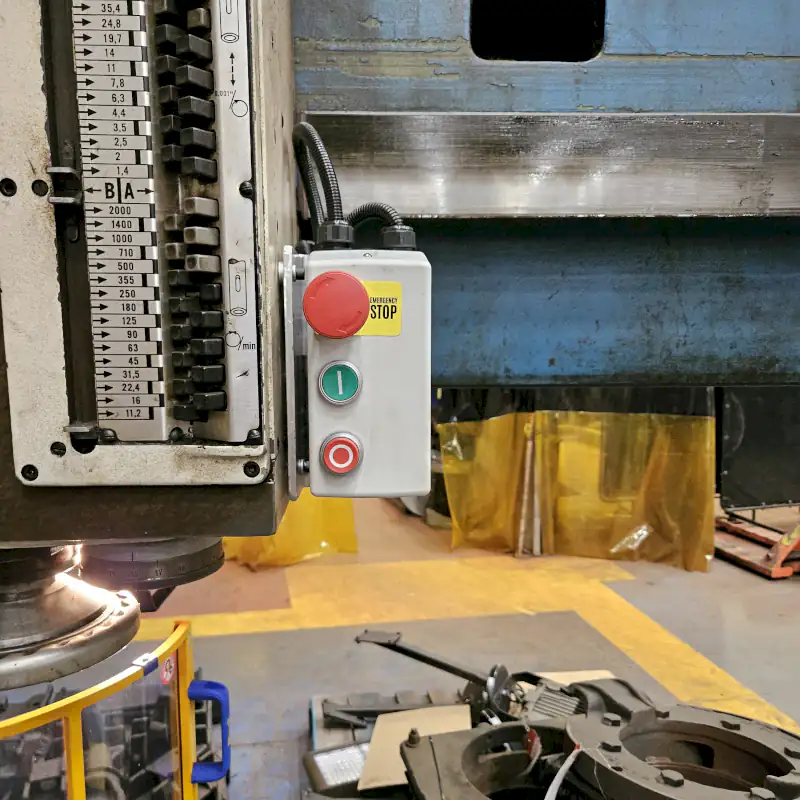

Anti-Restart Motor Starter Upgrade

These anti-restart motor starters are great for drill presses, bench grinders, and other small 120-volt machines. They prevent the device from starting automatically and add an emergency stop button when an emergency arises.

We can also add upgrades such as a key to prevent unauthorized use and a LOTO (lockout, tag out) device. If you’re unsure if this thing is right for your machine, call us – we are a friendly bunch of people and would love to help you.

Do you have a three-phase motor that runs on 208v or higher? The motor starter on this page is not the right choice for 3-phase motors. Click here to see our 3-phase motor starters.

Anti-Restart Protection

A motor starter prevents machines and motors from starting back up after a power failure.

You will often see the term “anti-restart protection” when dealing with machine safety. Here’s a simple test to see if your machine needs an electrical upgrade:

- Start the machine and leave it running.

- Please turn off the breaker or disconnect the machine’s switch and wait for it to stop.

- Turn back on the breaker or disconnect the switch and check if the machine starts up again.

If you see the machine turn back on by doing this test, you must upgrade the electrical system to include anti-restart protection. If you are unsure, please get in touch with one of our electrical specialists, and we will be happy to assist you.

OSHA recognizes NFPA 79:7.5.3, which states that all machines must have a magnetic starter to prevent accidental or unintentional machine restarting. A magnetic starter or contactor is inside our anti-restart motor starters.

On machines such as drill presses and grinders that use mechanical power switches like light switches, the machine is always powered on until a person physically pushes a button or flips a switch. If a power failure happens, the device will turn off because it has no electricity from the outlet. When the power comes back on, the device turns on automatically! Not only is this dangerous, but it is entirely avoidable.

Motor starters prevent the machine from automatically resetting the circuitry and unloading the motor from the power source. A machine operator must press a button for the motor starter to engage and start the machine.

It prevents restarts after using a safety guard.

Limit and interlock switches are not designed or intended to control motor current loads. Without a motor starter, interlocked safety guards would stop the machine if opened and start immediately after closing the guard. Not only is it hazardous to wire something this way, but it is also a dangerous misuse of the interlock switches.