Ferndale Safety Engineering Projects

Custom-Made Centerless Grinder Guarding

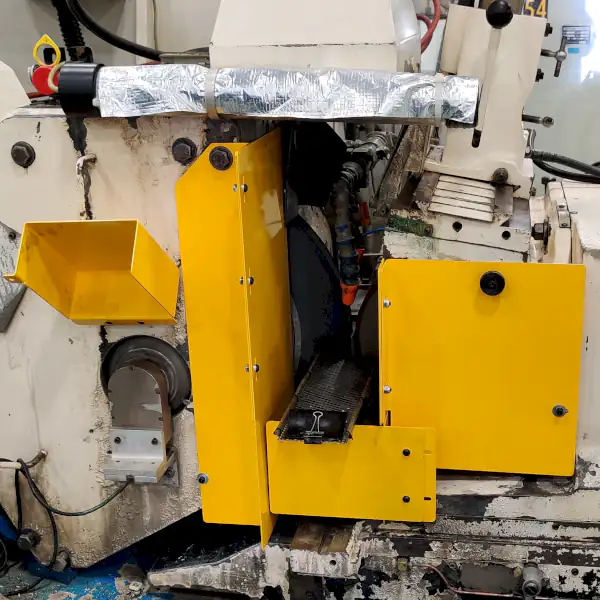

We were asked to cover the openings on an old centerless grinder as much as possible.

The Ferndale Safety engineering team created custom steel guards to fit this particular machine.

Project Overview: Custom Centerless Grinder Safety Guarding System

Our custom centerless grinder guarding system is a turnkey solution designed to protect operators from the inherent risks of high-speed grinding operations. With fully automated safety guards, this system is built to prevent dangerous interactions with the machine’s rotating components and flying debris, while ensuring the smooth operation of the grinder.

What is a Centerless Grinder?

A centerless grinder is a machine tool used for precision grinding of cylindrical parts. Unlike traditional grinders, the workpiece is supported between two wheels—one for grinding and one for regulating the speed—allowing it to be processed without the need for centering or supporting the workpiece with a fixture.

What Are the Risks?

Centerless grinders operate at high speeds, exposing operators to several potential hazards. These risks include:

- Entanglement and Drawing-in Hazards: Loose clothing, hands, or tools can be caught between the wheels or in the rotating parts.

- Abrasion and Contact Injuries: The grinding wheel can cause severe injuries if operators come into direct contact with it.

- Projection Hazards: High-speed grinding can lead to the ejection of metal fragments, abrasive particles, or, in rare cases, fragments of the grinding wheel itself.

The Ferndale Safety Solution

Do you have a safeguarding project?

Ferndale Safety can help you with:

Please fill out the form below so that one of our safety experts can call you. Alternatively, you can click here to send us a message.