Ferndale Safety Engineering Projects

Big Surface Grinder Enclosure

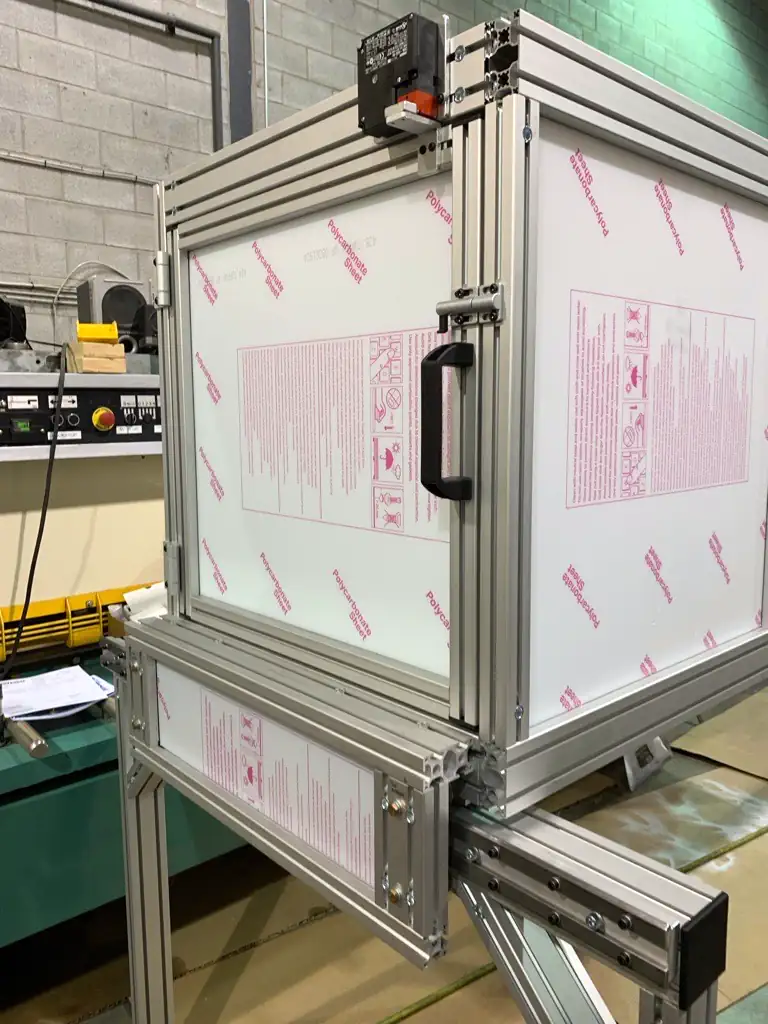

Ferndale Safety custom-designed, built, and installed a large CNC surface grinder enclosure.

Built and designed to the customer’s specifications, Ferndale Safety completed this custom project on time and within budget, leaving the customer very satisfied with the results.

Video of Sliding-Track System

The Requirement

Smooth-Sliding Track

The Ferndale Safety engineering team developed a super-smooth sliding system for horizontal table movement against the machine.

Schedule a call with us today.

Ferndale Safety can help you with:

Please fill out the form below so that one of our safety experts can call you. Alternatively, you can click here to send us a message.