Connecting Safety Interlock Switches in Series

July 29, 2024 in Machine Safety Blog byTo save on costs and simplify wiring, a standard method of connecting multiple interlock switches is daisy chaining them. Daisy chaining means connecting several devices in a linear series. But doing it that way may present what is called fault-masking, which are faults that the safety system may not detect.

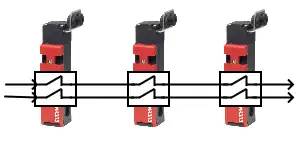

Daisy Chaining Mechanical Interlock Switches

In this example (see image), three key-actuated interlock switches are connected in series. Each switch has two normally closed contacts that open when the key is removed.

Daisy chaining switches together in this way may be an attractive solution because less cable is used, especially when the switches are close together.

Fault Masking

Fault masking is a critical issue that arises from connecting safety interlock switches in series in machine guarding safety circuits, particularly in high-risk applications.

While daisy chaining interlocks is cost-effective, it can lead to a loss of safety function due to undetected faults like short circuits. Fault masking occurs when a fault in the safety circuit goes undetected, potentially compromising the safety function of the system.

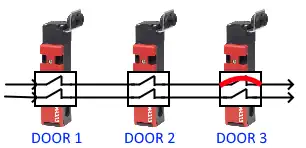

Now, let’s introduce a fault in the system. In this example, one of the contacts is shorted or welded shut on door 3, as shown in the image below.

What happens? Well, it depends on which door is opened.

Door 1 open:

If door 1 is open and then closed, the system functions normally. Perhaps if the door is open, the machine stops, and when it is closed again, the operator can push the start button to resume operation.

Door 3 open:

If door 3 is open, the system will shut down, but now the safety relay detects the fault (Only 1 of the two contacts changes state) and goes into a fault mode.

After closing door 3, the safety relay may need to be manually reset or the power cycled to clear the fault. The safety relay can also be reset by closing door 3 and opening and closing door 1 or 2. Of course, this can also happen if all the doors are open.

So, in brief, the safety relay can be reset by opening and closing the doors without detecting the fault and allowing the machine to restart and continue operation, even though the fault remains.

Solutions to Fault Masking

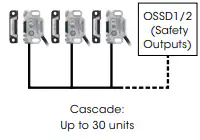

When connecting multiple switches together, Ferndale Safety uses RFID switches. These switches already have self-monitoring electronic outputs, built-in internal diagnostics, and internal dual-channel cat-IV architecture.

An alternative is to use one safety relay per interlock switch, or if you have more than three interlock switches, a safety PLC or controller with multiple inputs will work. This way, each interlock switch will have its dedicated safety device.

References

Relevant standards addressing this issue include ISO 13849-1, which requires that safety-related parts of control systems detect at least 60% of faults, and ISO 14119, which provides design principles for interlocking devices. ISO/TR 24119 further details the evaluation of fault masking and its impact on diagnostic coverage.