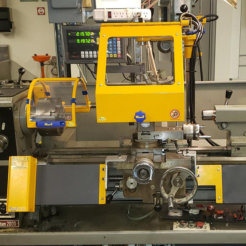

Lathe Chip Shields and Carriage Guarding

Showing all 7 resultsSorted by popularity

Understanding the Lathe Chip Shield and Its Importance

Lathes, as dynamic and indispensable tools in the manufacturing sector, involve many cutting processes that produce chips and use coolants to keep the equipment from overheating. While these processes are essential for smooth operation and achieving the desired workpiece results, they can pose certain risks to operators if not appropriately managed. Here’s where the lathe chip shield comes into play.

Key Features of the Lathe Chip Shield:

- Barrier Protection: The primary function of the lathe chip shield is to serve as a protective barrier between the operator and the point of cutting. It acts as a defensive wall, stopping unwanted debris and splashes from reaching the operator.

- Coolant Management: Coolants, while crucial for the operation, can be messy and, if projected with force, could be harmful. The shield prevents coolant from spraying towards the operator, ensuring a cleaner and safer working environment.

- Enhanced Visibility: Modern lathe chip shields are often designed with robust materials like polycarbonate, allowing operators to monitor the cutting process closely without exposing themselves to potential hazards.

- Durability: These shields are built to withstand the high-pressure environment of lathing operations, ensuring they remain effective and undamaged even in intense working conditions.

Benefits for Operators and Workspaces:

- Safety First: With chips and coolants contained, operators can focus on the task at hand without the constant worry of debris or splashes, reducing the risk of accidents and injuries.

- Cleaner Workspace: By preventing the ejection of chips and coolants, the shield ensures that the surrounding area remains relatively clean, reducing cleanup time and increasing overall productivity.

- Extended Tool Life: By managing chips and coolants effectively, there’s a reduced chance of unwanted buildup on the tool, potentially extending its lifespan.

The lathe chip shield is more than just an accessory; it’s vital for any lathe operation, prioritizing safety, efficiency, and quality results. Investing in a robust chip shield ensures the cutting process remains seamless while keeping the operator’s well-being front and center.

Your lead screw also needs to be covered! Click here for more information.