Ferndale Safety Engineering Projects

Automated Surface Grinder Safeguarding

We designing and built a fully automated safety upgrade for eight surface grinders at two major customer facilities, one near Montreal, Canada, and the other in Portland, OR.

This represents a significant milestone for our company, as it is the first project of its kind in our history. We are proud to be at the forefront of enhancing safety for this critical equipment.

Portland, Oregon, USA

Montreal, QC, Canada

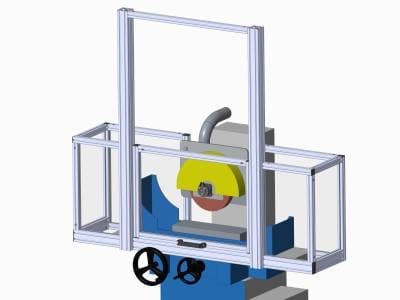

Project Overview: Surface Grinder Safety Enclosure with Automated Grinding Wheel Guarding System

This project’s heart is a comprehensive, turnkey solution: a custom-designed surface grinder safety enclosure equipped with an automated grinding wheel guard. This solution reflects our commitment to ensuring the highest safety, efficiency, and usability standards.

What’s a surface grinder?

Surface grinding is a process to make a flat, smooth surface on steel parts. A surface grinder is a machine tool that facilitates the surface grinding process.

What are the risks?

Surface grinders pose significant safety risks due to the high-speed rotation of the grinding wheel. This wheel continues spinning even when the machine is not in active use, often for reasons related to balance and tolerance. The dangers include:

Projectile Risk: The grinding wheel may project fragments if an impact occurs or if the wheel has an internal defect, leading to potential wheel explosions.

Entanglement and Drawing-in Hazards: Loose clothing or body parts can be caught in the rotating wheel.

Abrasion and Burning: The high-speed wheel can cause serious skin injuries or burns.

Video

The Ferndale Safety Solution

Our engineers and safety experts came up with a solution that:

Features

Advanced Safety Guarding

Ferndale Safety custom-designed this hood cover to protect users from the grinding wheel. The cover automatically opens and closes quickly to minimize the impact on work.

User-Friendly Design

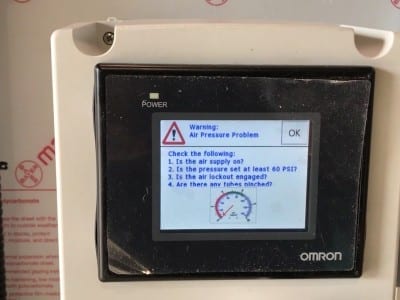

Ferndale Safety wanted this surface grinder safety system to be as user-friendly as possible. The system performs multiple self-checks and displays a detailed error message with possible solutions directly on the touch screen. On-screen icons and graphics give the user a quick visual indication of what is wrong.

Safety Through Engineering

Ferndale Safety’s design engineers, machine safety experts, and technicians work together to offer the best safety product for the client. Multiple CAD designs and process flow charts were handed back and forth with the end-user to fine-tune the final product.